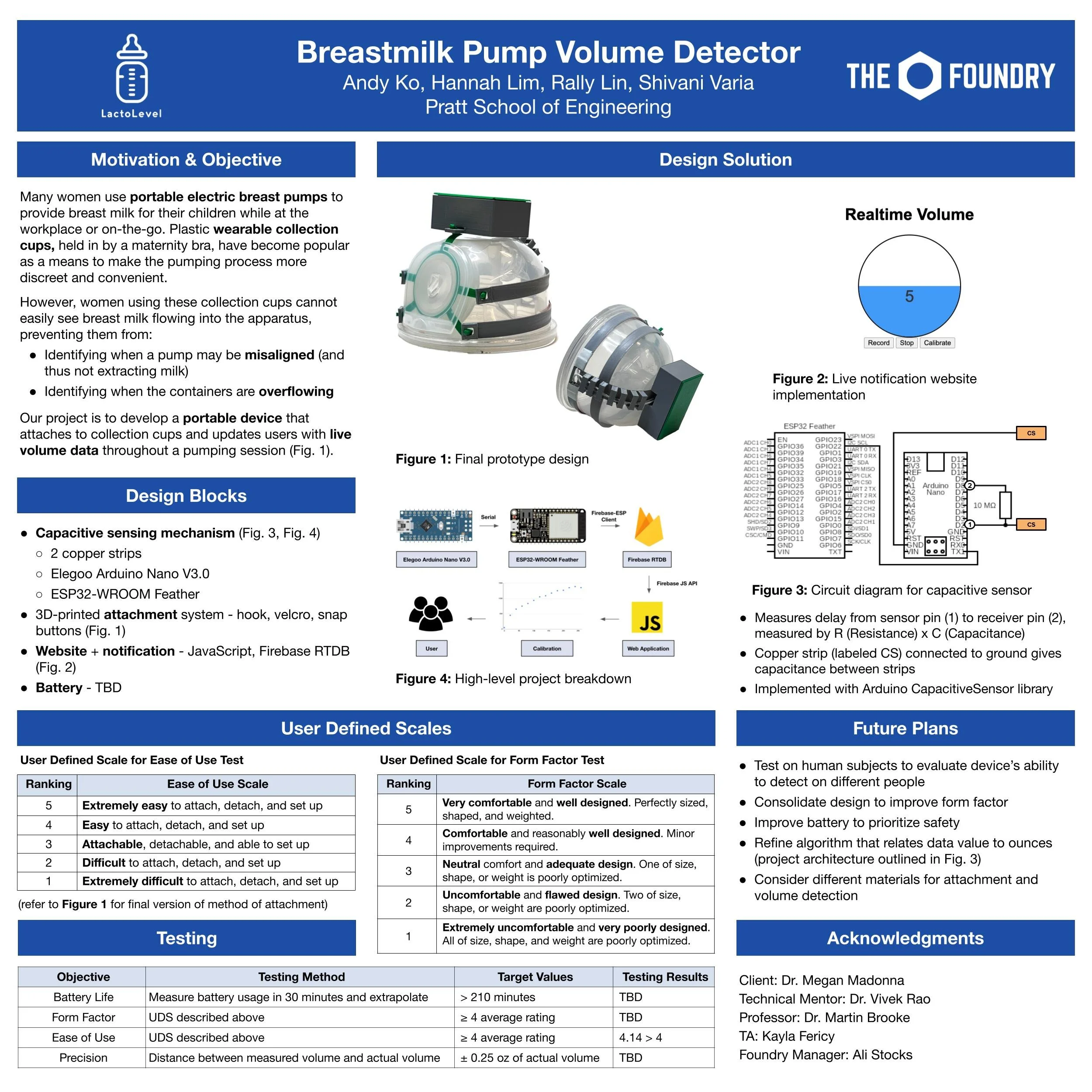

Breastmilk collection cup capacitive sensing

Context

Many women use portable electric breast pumps to provide breast milk for their children while at the workplace or on-the-go. Plastic wearable collection cups, held in by a maternity bra, have become popular as a means to make the pumping process more discreet and convenient. Our client, a new mother who pumped while at work, communicated to us that it was hard to discreetly tell if milk was being expressed, how much milk was being expressed, and if milk was about to overflow from the collection cup container. These issues can cause more serious problems such as infection and decreased supply over time.

Solution

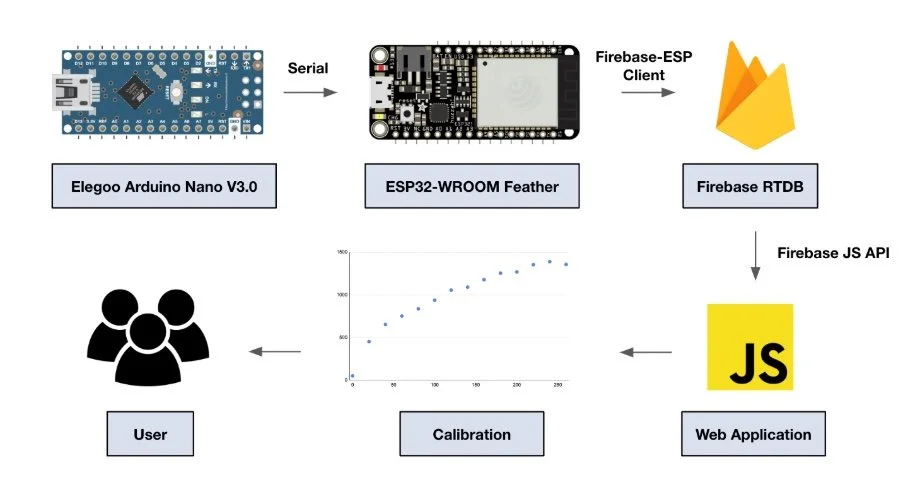

We developed a portable, detachable device that updates users with live volume information during a pumping session. Capacitive sensing was implemented using two copper strips acting as capacitor plates, with a 10 MΩ resistor connecting the Arduino Nano’s send and receive pins. The Arduino measured the RC delay—how long it took the receive pin to detect a voltage change—which varied with changes in capacitance between the strips. These capacitance values, processed through the Arduino CapacitiveSensor library, were sent to the ESP32 module and displayed in real time via a Firebase-connected web app. The web app enabled the user to easily see the volume through a visual, as well as calibrate to zero before pumping began to increase the precision of volume sensing. The copper strips were affixed onto the collection cup with a 3D printed apparatus that could be removed and cleaned.

Skills

Prototyping, CAD, Arduino C++, Circuit design, Sensor calibration

Decision making, Budgeting, Teamwork

Prototype evolution: Low fidelity, to medium fidelity where the ultrasonic sensor was ruled out and the strip method was decided upon

High level breakdown

Solution brainstorming

Prototypes of attachment system